Terminology in cargo securing

- STF – Standard Tension Force

- SHF – Standard Hand Force

- LC – Lashing Capacity

- Direct pull / Strapping

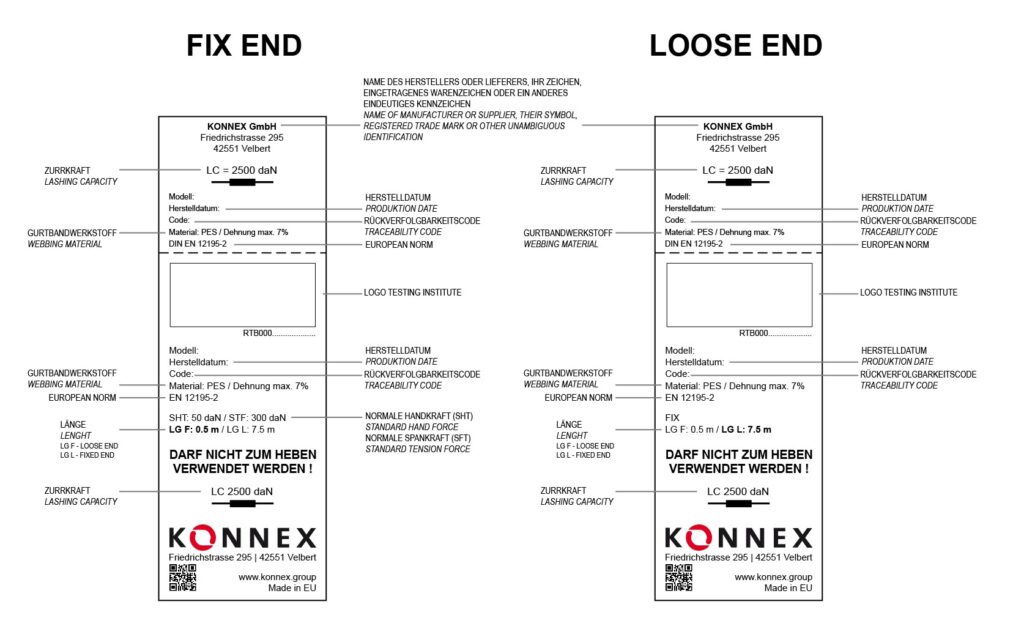

- Label explanation

- Operating pressure and pull ratchets

- Explore KONNEX:

- Get in touch with us:

Units of measurement:

1 kg = 9.80665 N

1 daN (Dekanewton) = 10 N ≈ 1 kg

50 kN = 5.000 daN ≈ 5.000 Kg = 5.0 t

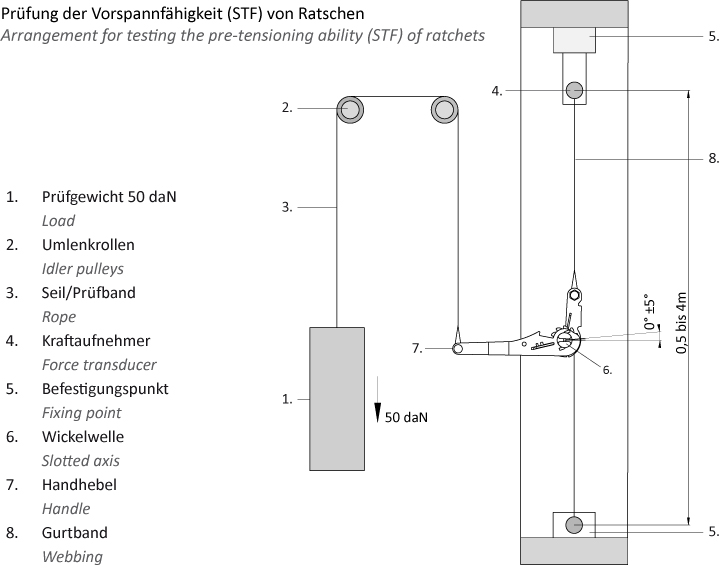

STF – Standard Tension Force

The abbreviation STF “Standard Tension Force” stands for the pretensioning force also called “Normal Tensioning Force”, this describes the force of the lashing strap. Put simply, with an STF value of 350 daN: you pull or push on a ratchet lever with exactly 50 daN (SHF) and can lift/move a weight of 350 kg with this force. The main reason for high pretensioning forces are the high-quality products, in this case the ratchet and the lashing strap, which have been optimized for your application. The STF value to be achieved is defined by the European standardization: STF = min. 0.1 x LC and max. 0.5 x LC

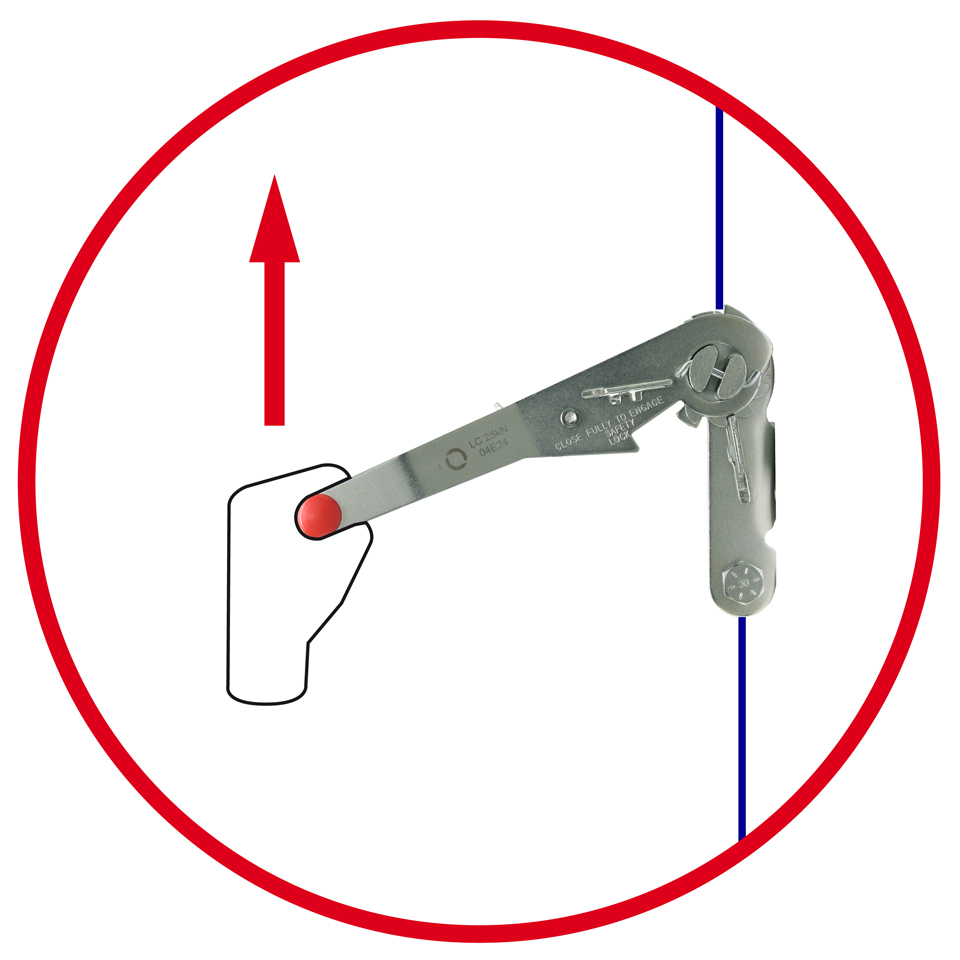

No aids such as rods or levers etc. may be used unless they are part of the clamping element.

Illustration: Pressure ratchet

| LC (Lashing Capacity) | STF min. | STF max. |

| 400 daN | 40 daN | 200 daN |

| 750 daN | 75 daN | 375 daN |

| 1.000 daN | 100 daN | 500 daN |

| 1.500 daN | 150 daN | 750 daN |

| 2.000 daN | 200 daN | 1.000 daN |

| 2.500 daN | 250 daN | 1.250 daN |

| 3.500 daN | 350 daN | 1.750 daN |

| 5.000 daN | 500 daN | 2.500 daN |

Cam buckles and heavy-duty pressure ratchets

The specification of the normal hand force (SHF) and the normal tension force (STF) can be omitted on labels of lashing straps with cam buckles if these lashings are not designed by the manufacturer for the intended use – tie-down lashing.

Cam buckle

As a rule, no or only slight tensioning forces are achieved with cam buckles, so that the intended use is limited to direct lashing procedures or bundling.

Heavy-duty pressure ratchets

The same applies mutatis mutandis to many heavy-duty lashing straps with nominal widths of 75mm to 100mm. The tensioning elements used in these lashing straps also generally do not achieve any useful tensioning forces for the intended use – tie-down lashing, but are used for direct lashing due to their high LC values.

* All products in our assortment of cargo safety are tested according to DIN EN 12195-2. STF – Standard Tension Force according to DIN EN 12195-2, always applies to a lashing belt system (ratchet, webbing and end fittings). The webbing, its length, composition, elongation, sewing and material thickness have a very large influence on the STF value of a lashing belt system. The STF value for pull- and pressure ratchets is given by us only for guidelinde.

Example:

71CQ050 Pressure Ratchet 50mm – 50kN

Breaking Strength (BS) 50 kN corresponds to a LC of 25 kN (1/2 BS)

The STF value here must be between (0,1 x LC) 250 daN and max. (0,5 x LC) 1.250 daN.

Structure:

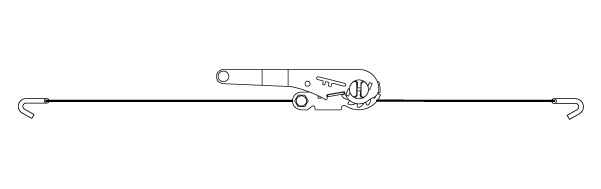

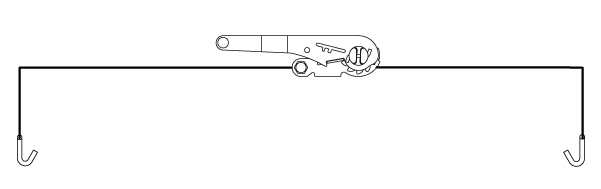

A two-part tensioning belt consists of one tensioning element: a pressure or pull ratchet, webbing and end fittings. A tensioning belt is divided into a loose end and a fixed end. Both parts are marked with a label in accordance with the DIN EN 12195-2 standard, so that the product can always be traced precisely.

Both the fixed end and the loose end have an end fitting, e.g. a pointed hook, flat hook or snap hook, these are thoroughly selected depending on the application.

The tensioning element is called a pressure ratchet or pull ratchet

The most commonly used ratchet is the pressure ratchet whose STF value (Standard Tension Force) reaches values up to 350 daN. If more force is required, an ERGO long lever ratchet, also known as a pull ratchet, is used, which achieves STF values of up to 800 daN, depending on the design.

SHF – Standard Hand Force

The abbreviation SHF “Standard Hand Force” describes the force (50 daN) that must be applied to the ratchet lever according to the European standardization (DIN EN 12195-2) in order to determine the STF value for the system (ratchet, lashing strap and end fittings). This force is also called hand force – force of the user.

LC – Lashing Capacity

The value LC “Lashing Capacity” stands for the permissible lashing force. It indicates when the load limit for the lashing system in straight pull (direct pull) is reached. This value is determined from the breaking strength.

Example:

71CQ050 Pressure Ratchet 50mm – 50kN

Breaking Strength (BS) 50 kN = LC 25 kN (1/2 BS)

LC – direct pull

Example: Pressure Ratchet 50mm – 50kN

LC = 2500 daN

– Ratchet

– Fixed end with end fitting

– Loose end with end fitting

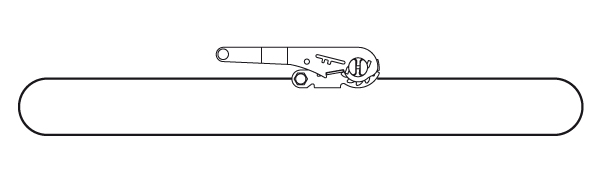

LC – strapping

Example: Pressure Ratchet 50mm – 50kN

LC = 5000 daN

– Ratchet

– Fixed end with end fitting

– Loose end with end fitting

– Ratchet

– Lashing strap

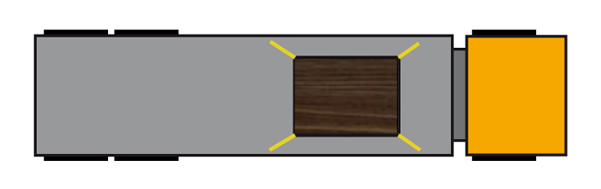

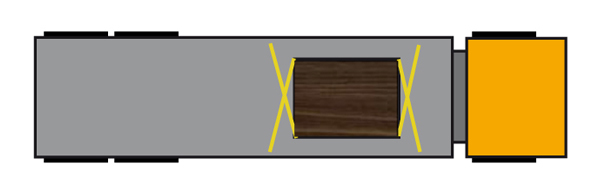

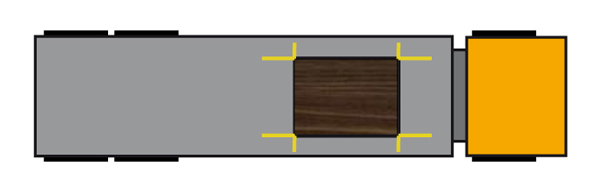

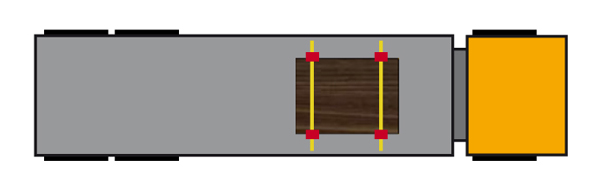

Direct pull / Strapping

Direct pull

If very heavy loads are involved, they are secured by direct pull. In the case of direct lashing, the lashing straps are attached to the load’s attachment point and to the lashing points on the loading surface. In contrast to strapping, the load is not pressed against the truck floor.

Strapping

Strapping is a non-positive load securing method. In this case, the belts are placed around the load and tensioned, pressing the load against the floor. To prevent damage to the load or the lashing straps, edge protectors are used here.

Label explanation

- PES (polyester) = blue label (standard LABEL)

Working range: -40 °C to + 120 °C

Resistant to mineral acids, but not to alkalis. - PA (polamide) = green label

Operating range: -40 °C to + 100 °C

Resistant to alkalis (substances that form alkalis with water), but not to mineral acids. - PP (polypropylene) = brown label

Working range: -40 °C to + 80 °C

More resistant to acids and alkalis (except some organic solvents).

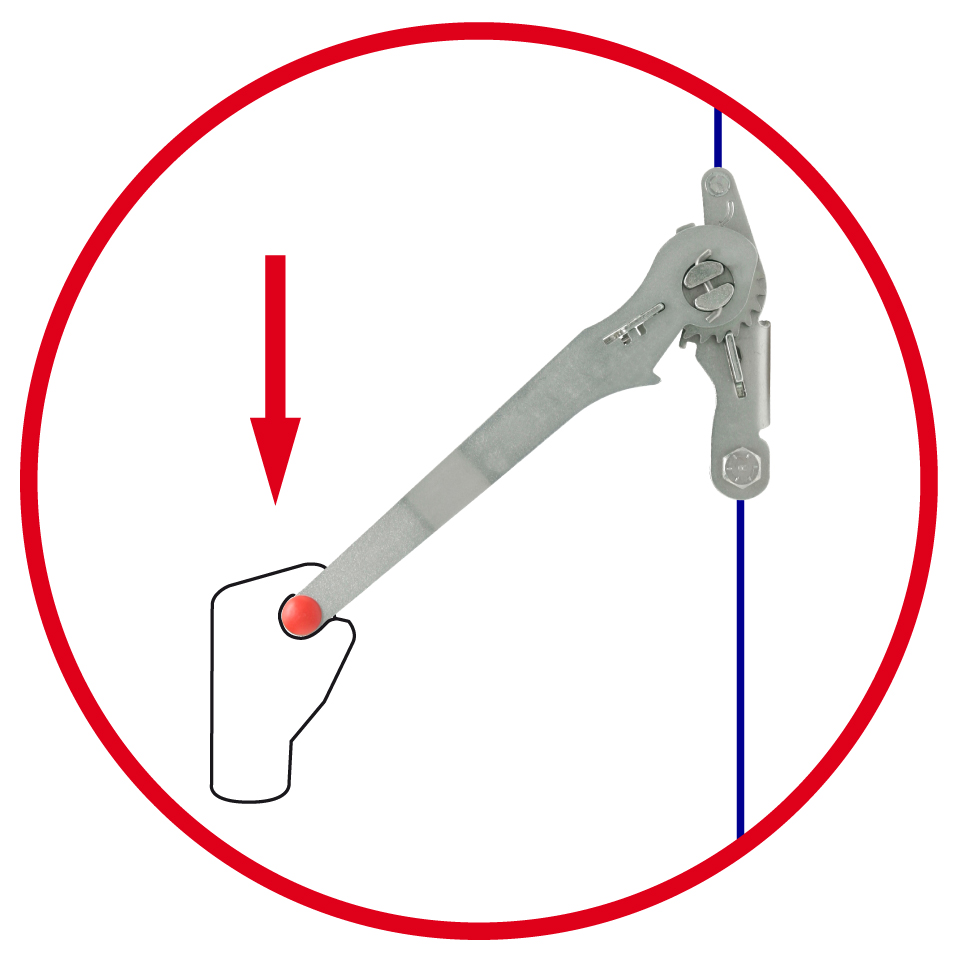

Operating pressure and pull ratchets

Tensioning: Open the ratchet lever from the lever lock and bring the slot of the belt holder into position. Insert the end of the strap (loose end) into the slot in the strap holder and pull through by hand so that the strap is taut before tensioning the ratchet. To tighten, move the ratchet lever back and forth until the required pre-tension is achieved. Then close the lever again.

Pressure ratchet

Pull ratchet

Release: To release the tension, the lever of the ratchet is fully opened; this is only possible if the pawl is pulled at the same time. The strap is then pulled out of the ratchet.

Important: Before releasing the tensioning element (pressure and pull ratchet, clamping lock), it must be ensured that the load is still secure even without securing and that the unloading process is not jeopardised.